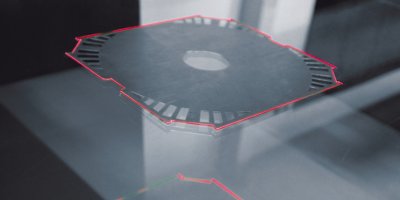

Laminations

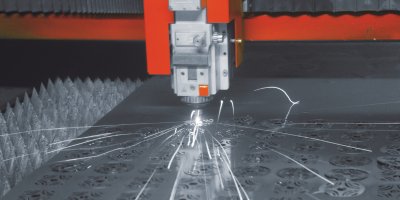

High-precision laser cutting represents cutting-edge technology in the field of electric motors and generators, offering several advantages over traditional stamping methods, including the absence of burrs, high precision, and no initial investments required.

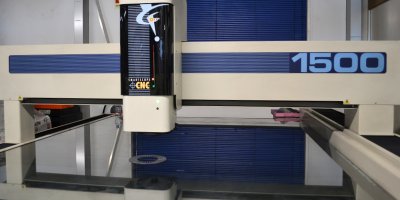

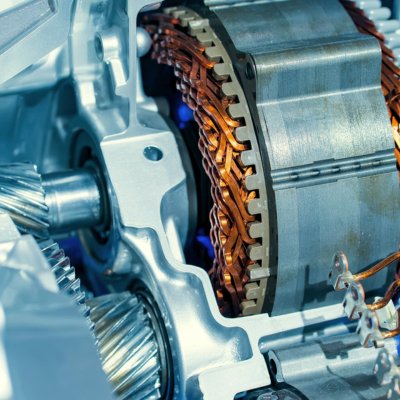

Solutions

We offer complete solutions for prototyping and producing electric motors and generators.