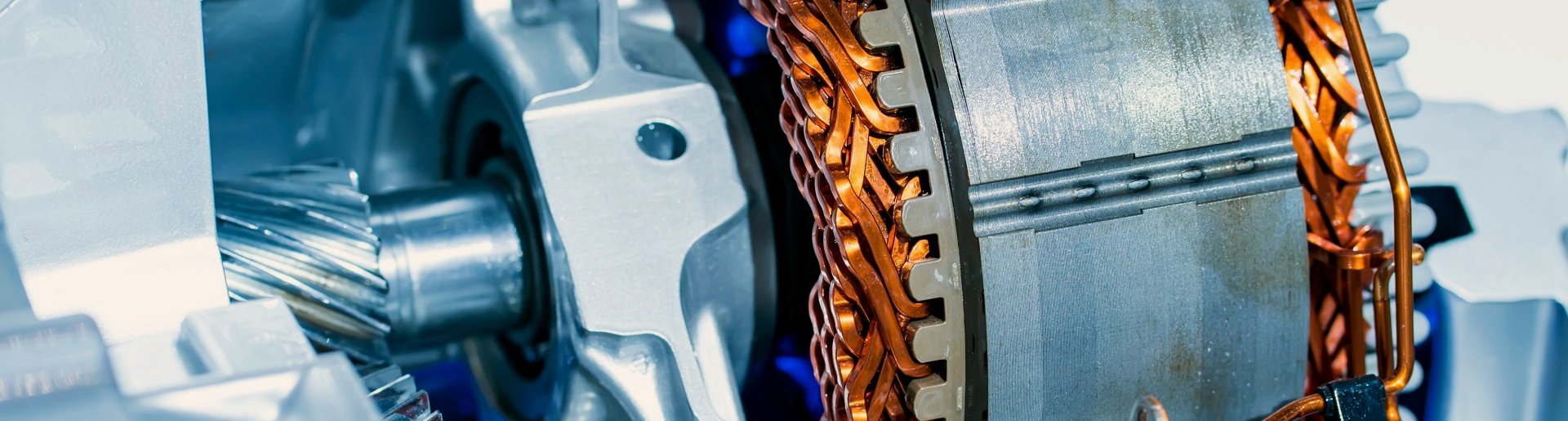

E-mobility

Prototyping of electric motors and production of small/medium series

Laser cutting & stacking

Our facility operates a dedicated laser cutting department for electric motor laminations, featuring 3 custom fiber laser cutting installations. These installations ensure the highest level of precision and consistency in cutting throughout the entire production process.

Features

State-of-the-art fiber laser on silicon steel sheet: minimal thermal impact, maximum precision.

Precision

Precision starting from ± 0.025 mm, roundness < 0.03, concentricity < 0.01

Stock

Magnetic lamination EN10106 pre-insulated with BACKLACK and C5, also for high frequency applications (NO). Thicknesses from 0.2 to 0.65 mm.

Quality

Inspection of loose laminations with optical CMM, resolution 0.5µm

Rotor & stator stacking

Bonding technology BACKLACK

(including fast-bonding)

Laser welding

Turning & honing

Measurement of stacking factor and dimensional report with virtual reality

Products

BLDC Motor

FEM Motor

SPM Motor

SRM Motor

IPM Motor

Additional services

- #01Fast-prototyping service with reduced lead times for prototyping

- #023D inspection of the pack with a report made in virtual reality

Products made in Aussafer

Quality

We create products that satisfy all the requirements requested by the customer, subjecting them to rigorous controls.

Aussafer Due is an ISO 9001:2015 certified company.